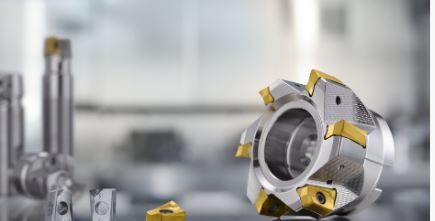

SECO end mills, grooving cutters:

SECO offers users the most comprehensive, advanced and comprehensive collection of end mills and grooves on the market today. Therefore, no matter what workpiece material, depth of cut or tolerance requirement, SECO Milling Cutter can meet and optimize. Thereby helping to save costs, increase profits and maintain competitive advantages.

The SECO line of end mills and grooves are diverse in models, types and applications:

1/ 2-blade Tubor – Single-sided insert This is a slot mill suitable for most rough, semi-finished and fine workpieces, these highly versatile designed tips offer a long tool life and high precision through optimized characteristics that reduce heat generation and cutting forces. The body is coated, pre-hardened with two different pitch profiles for tight tolerances and high accuracy. This surface not only protects the tool from wear, but also prevents chipping caused by welding on the tool body. Turbo tool heads with precision milled insert holders improve eccentricity, stability and tool life by providing optimal contact between the tool body and the insert. Cooling channels support high yields and promote excellent chip evacuation.

H1. Turbo SECO ranh Edge Milling Tool

2/ SQUARE ZOMX – 4 blades – Two cutting surfaces

Less power consumption, lower cost, smoother cutting and reduced disassembly time. Minimize vibration.

Long service life, reduced vibration and improved process accuracy, thanks to the docking protection of three contact zones in the bag along with a screw in the middle. Environmental friendliness

.

H2. SQUARE ZOMX Milling Cutter – 4 Blades – Two Sections

3/ SQUARE T4 – 4 CUTTING BRACES, DOUBLE BENEFITS

Designed for rough and semi-finishing milling, the Square T4 features four cutting edges and an innovative tangential tool design that increases the contact surface area between the insert and the tool body resulting in a good surface finish in sawing applications. slotting, edge milling and press milling.

Square T4's reliable, strong insert holder combined with multi-blade insert optimizes cutting stability and allows 90 degrees of smoothness to be formed. The insert is tangentially inserted into the tool so that cutting force is applied to the thickest parts of the insert, allowing the manufacturer to achieve the required strength for increased depth of cut with small diameters. The Square T4 also offers smooth cutting through a positive rear angle with variable lead angle on the blade.

H3. SQUARE T4 Milling Cutter – 4 CUTTING BRACES, DUAL-sided INSERT

4/ SQUARE 6 – 6 CUTTING BRACES, DOUBLE BENEFITS

Seco's line of Square 6 end mills and end mills fulfills the need for additional economy in wall and slot milling. This unique miller uses a triangular insert with three cutting edges on each face – a total of six – to reduce cost per cutting edge. The insert is held in place via a stiff center screw positioned in the same direction as the cutting force and the wiper surfaces optimize surface finish. The 90° setting angle ensures a true 90° right angle in one milling operation, eliminating the need for a second operation and saving production time and costs.

H4. SQUARE Milling Cutter 6 – 6 CUTTING BRACES, DUAL BENEFITS

5/ Grooving Mills for Heavy Materials These versatile 90° grooving end mills and end mills for heavy duty roughing applications offer large cutting depths and high feeds for consistent performance Very good metal removal rate and stability

H5. Groove milling cutter for heavy materials

6/ SQUARE SHOULDER MILLS Applications for advanced cutting materials. Allows to take advantage of the benefits of this cutter, such as higher cutting speeds. When applied correctly for the right applications, PCBN, PCD and ceramics offer outstanding strengths for horizontal milling productivity.

H6. Dao phay SQUARE SHOULDER MILLS

0968.40.31.38

0968.40.31.38 Chat Zalo

Chat Zalo Chat Facebook

Chat Facebook